Key Takeaway:

Wind turbines use traditional blade designs instead of squirrel cage rotors due to their efficiency, scalability, and cost-effectiveness. While bird mortality is a concern, extensive research and mitigation measures are being implemented to minimize the impact on bird populations.

Renewable energy has gained significant attention in recent years as the world strives to reduce its reliance on fossil fuels and combat climate change. One of the most visible symbols of clean energy is the wind turbine. These towering structures, with their massive rotating blades, harness the power of the wind to generate electricity. However, concerns have been raised about the impact of wind turbines on bird populations, leading some to question why squirrel cage rotors aren’t used instead. In this article, we’ll explore the reasons behind this design choice and delve into the issue of bird mortality.

Wind Turbines

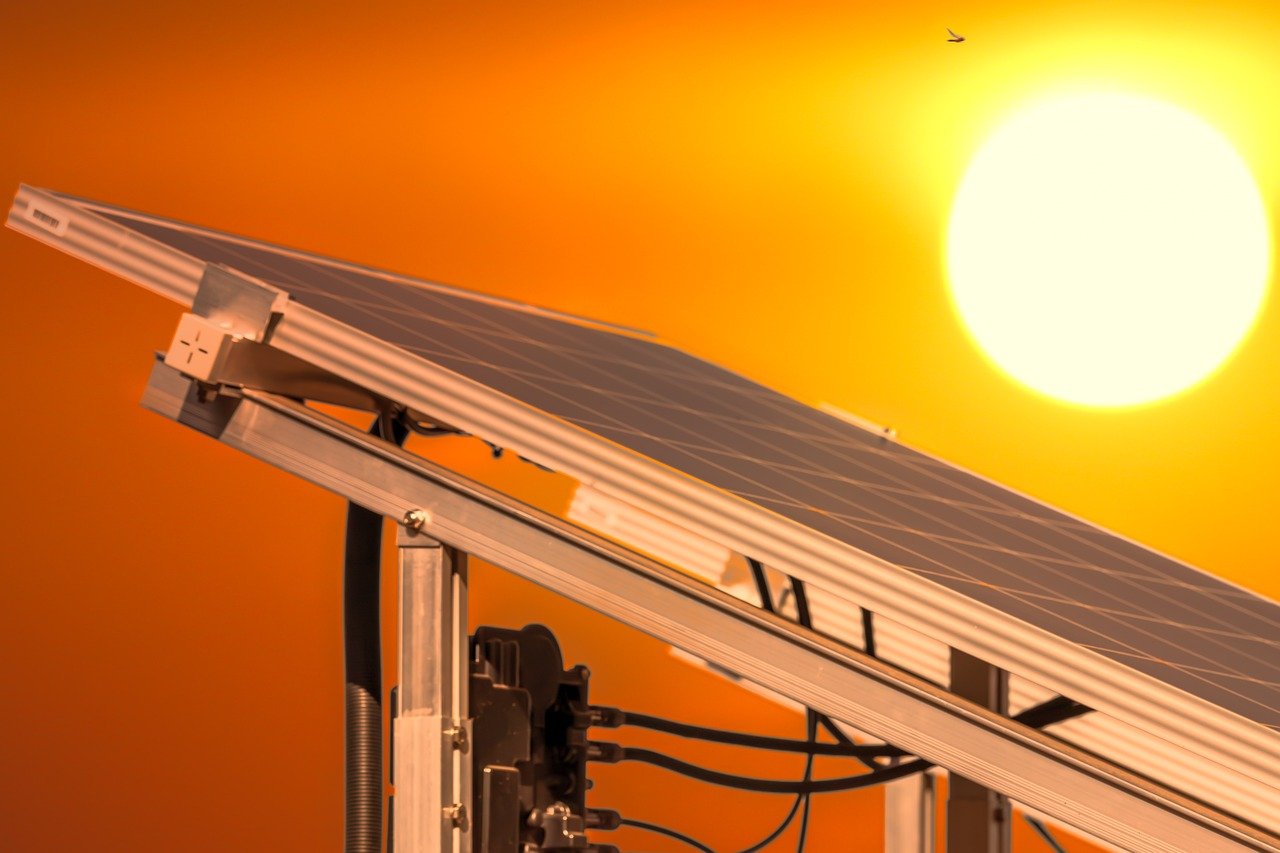

To understand why squirrel cage rotors aren’t commonly used in wind turbines, let’s first establish what wind turbines are and their purpose. Wind turbines are large structures that convert the kinetic energy of the wind into mechanical energy, which is then converted into electricity. They consist of three main components: the tower, the nacelle, and the rotor.

The tower provides height, allowing the rotor to capture the stronger and more consistent winds found at higher altitudes. The nacelle houses the generator, gearbox, and other components responsible for converting the mechanical energy into electricity. Finally, the rotor, consisting of two or three large blades, captures the energy from the wind and transfers it to the generator.

Explanation of the Traditional Blade Design

The current design of wind turbine blades has evolved over decades of research and development. These blades are carefully engineered to efficiently capture wind energy and withstand the forces exerted by strong winds. The size and shape of the blades are optimized to maximize power output while minimizing material usage and cost.

The blades are typically made from fiberglass or carbon fiber-reinforced composites, which provide strength while keeping the weight manageable. Their aerodynamic shape, with a curved surface on one side and a flatter surface on the other, allows them to generate lift, similar to an airplane wing. This lift force helps rotate the rotor and generate electricity.

Squirrel Cage Rotor Design

Now, let’s explore the concept of squirrel cage rotors and why they are commonly used in other applications, such as electric motors. A squirrel cage rotor is a type of rotor used in induction motors, which are widely used in various industries. It consists of laminated iron cores and conducting bars arranged in a cylindrical shape.

When an electric current flows through the conducting bars, it generates a magnetic field. This magnetic field interacts with the rotating magnetic field produced by the stator, causing the rotor to rotate. The design of the squirrel cage rotor allows for efficient and reliable operation in electric motors, making it a popular choice in many applications.

Comparison between Blade Design and Squirrel Cage Rotor

While squirrel cage rotors are efficient in electric motor applications, they are not suitable for wind turbines. There are several reasons why traditional blade designs are preferred for capturing wind energy:

- Efficiency: Wind turbine blades are carefully designed to extract the maximum amount of energy from the wind. Their aerodynamic shape and large surface area enable them to capture a significant amount of kinetic energy. Squirrel cage rotors, on the other hand, are not optimized for capturing wind energy efficiently.

- Cost: Wind turbine blades are manufactured at a large scale, often reaching lengths of over 100 feet. Despite their size, they are relatively cost-effective, thanks to advancements in materials and manufacturing processes. Squirrel cage rotors would require a significant redesign and manufacturing process, which could increase costs significantly.

- Scalability: Wind turbines come in various sizes, ranging from small turbines used for residential applications to massive turbines for utility-scale projects. The current design of wind turbine blades allows for scalability, with larger turbines having longer and more robust blades. Squirrel cage rotors would face challenges in scaling up to match the energy output of larger wind turbines.

- Bird Impact: Bird collisions with wind turbines have been a concern for environmentalists and bird conservationists. The large blades of wind turbines can pose a risk to birds, especially those flying in their vicinity. Squirrel cage rotors, by their design, would not pose the same risk to birds. However, it’s important to note that extensive research and mitigation measures are being implemented to reduce bird mortality, regardless of the rotor design.

Bird Mortality and Wind Turbines

The issue of bird mortality caused by wind turbines is a complex and multifaceted topic. While it is true that wind turbines can cause bird collisions, the extent of the impact on bird populations is still under study. Several factors contribute to bird mortality, including the location of wind turbines, bird flight patterns, and species behavior.

Research conducted by organizations such as the National Renewable Energy Laboratory (NREL) and the American Wind Wildlife Institute (AWWI) has shown that bird mortality associated with wind turbines is relatively low compared to other human-related causes, such as building collisions and habitat loss. Nonetheless, every effort is being made to minimize the impact on bird populations.

Mitigation measures are being implemented to reduce bird collisions, such as carefully selecting turbine locations, using radar systems to detect bird movements, and adjusting turbine operations during peak migration periods. Ongoing research is also focused on improving our understanding of bird behavior and developing bird-friendly wind turbine designs.

Pros and Cons of Squirrel Cage Rotor Adoption

While squirrel cage rotors offer advantages in terms of bird safety, their adoption in wind turbines comes with several disadvantages:

- Energy Output: Wind turbine blades are designed to efficiently capture wind energy and convert it into electricity. Squirrel cage rotors, not optimized for wind energy capture, would likely result in lower energy output compared to traditional blade designs.

- Maintenance: Wind turbine blades require regular maintenance and inspection to ensure optimal performance and safety. Squirrel cage rotors would introduce a new set of maintenance requirements, potentially increasing costs and complexity.

- Scalability: As mentioned earlier, squirrel cage rotors may face challenges in scaling up to match the energy output of larger wind turbines. The current blade design allows for flexibility and scalability across different turbine sizes.

- Cost: The redesign and implementation of squirrel cage rotors in wind turbines would require substantial investment and research. The cost-effectiveness of such a transition would need to be carefully evaluated before widespread adoption.

While squirrel cage rotors may offer advantages in terms of bird safety, the overall impact on renewable energy generation and the cost-effectiveness of wind turbines should be considered.

Future Developments and Research

Looking ahead, ongoing research and advancements in wind turbine design aim to address concerns about bird mortality. For example, researchers are exploring the use of visual and acoustic deterrents to steer birds away from turbine areas. Additionally, the development of wind turbine designs that are more bird-friendly, such as tubular towers and bladeless turbines, is being investigated.

It is important to recognize that wind energy is a crucial part of the renewable energy mix, contributing to the reduction of greenhouse gas emissions and combating climate change. While bird mortality is a concern, efforts are being made to strike a balance between renewable energy generation and bird conservation.

In conclusion, wind turbines use traditional blade designs instead of squirrel cage rotors due to their efficiency, scalability, and cost-effectiveness. While bird mortality is a concern, extensive research and mitigation measures are being implemented to minimize the impact on bird populations. As the world continues to transition to cleaner energy sources, it is imperative to find innovative solutions that address both environmental and energy generation challenges.